Together with social-economic development in Binh Duong province in particular and Southeast region in general, urban municipal waste is always a “hot problem” mentioned in environment protection programmes. Sai Gon and Dong Nai rivers’ basin more and more suffer from pollution caused by waste water; underground water source is also under risk of domestic and industrial waste.

Southern Binh Duong Water Environment Improvement project –phase 1- comprising collection sytem and waste water treatment plant with capacity of 17,650 m3/day which was taken into operation on May 31st, 2013 is under series of planned projects relating to sewerage and environmental sanitation approved by Binh Duong PPC at the Decision No. 4058/QĐ-CT dated 20/10/2003. Project’s objective is to collect and treat domestice waste water in Thu Dau Mot city to improve people’s living quality as well as cummunity’s health in the region, contributing to protecting Sai Gon river’s water source, ensuring a beautiful and sanitary urban.

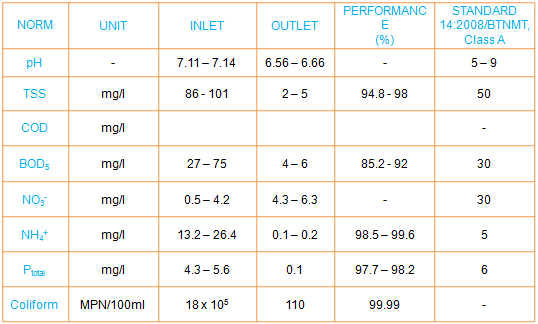

Technology selection is one of prioritiest concerns relating to treated waste water quality in compliance with standard QCVN 14:2008/BTNMT (class A), odor management to surrounding area is especially paid attention. BIWASE chose ASBR (Advanced Sequencing Batch Reactor) which is a suitable and optimum technology thanks to its advantages in comparison with traditional biology treatment technologies. The treatment plant includes inlet works items, ASBR, disinfection house, sludge solidifying tank, sludge pressing device, deodorizing hosue….In addition, ASBR is an appropriate technology to remove nitrogen and phosphorus to meet discharging standards in Viet Nam. definition of activated sludge circulation procedure is based on use of initial zone selected. This is an inlet waste water zone mixed with circulating water sludge mixture to strengthen forming procedure of sludge sediment and absorbing nitrogen and phosphorus in outlet waste water. ASBR is the only technology which can remove nutrient without any additional treatment process to meet Vietnamese discharging standards.

ASBR operation procedure is a simple biological treatment system and fully automatically operated and monitored by a PLC system:

- Its function is as a system controlled by time, allowing waste water continuously poured during all phases of process. This is suitable with changes of flow and inlet water weight. It is allowed to operate one batch in case of maintenance and in some conditions of low flow.

- Some processes can be continuously taken place in one batch such as biology oxidizing treatment to remove COD, nitrogen, phosphor and separate solid from liquid.

- Capacity expansion is easily made whilst waste water treatment still gets high effectiveness.

- Provide two separate treatment areas (pre-reacting and main reacting areas) by a hydraulic wall. Pre-reacting area is used as a biologic selecting unit to strengthen mutiplying of expected microorganism

- Having high flexibility.

- In addition, ASBR technology needs less land for construction than other ones, that allows to increase distance of buffering area, minimizing odor and not affecting to surrounding area, increasing 30% of design capacity in comparison with SBR traditional technology having same volume, easily to operate and low cost for operation (saving power).

Waste water treatment process at the plant includes 3 steps:

a. The 1st step treatment: preliminary treatment by mechanical method

Domestic waste water from households flow in primary sewer to the treatment plant through preliminary treating works, such as raw and fine screen, sandy sedimentation tank, system to separate oil, lubricant. Sediment, sand, oil and lubricant are removed at this preliminary treating works.

b. The 2nd step treatment: treatment by biology method with activated sludge of ASBR technology.

At this process, most of pollutant in waste water shall be removed by a biology treatment process taking place in ASBR tank. ASBR’s function allows inlet of wastewater to keep on going through different steps of the whole treatment process. These steps are follows:

- Reacting-air blowing and mixing procedures are applied to get expected biology treatment effectiveness.

- Sedimentation-pausing air blowing and mixing so that suspending solid will sediment at the bottom of tank and clean water is above. The tank still receives inlet of waste water through pre-reacting cell.

- Discharging-treated waste water is sucked out while inlet of waste water still goes into the tank. Surplus sludge is discharged in this step.

c. The 3rd step treatment: Ultra Violet disinfection (UV)

Sludge compressing and deodorizing systems are also advanced equipments to thoroughly treat chemicals causing pullution such as Amoniac, Hydro sunfua, mercaptan ect… generated during waste water and sludge treatment process.

Beside that, an online monitoring measuring system is also equipped to serve for all procedures pre-, in- and post-treatment.

Testing result of waste water before and after being treated.